G Code List Siemens

G-code (also known as RS-274) is the name of the most prevalent programming language for computer numerical control (CNC) in computer-aided design and manufacturing (CAD/CAM). G-code provides metric-based numeric control of CAM-controlled equipment such as CNC milling machines.

G-code is the simple programming language for CNC machines. It consists of lines of code that are organized in blocks. Each block controls one CNC machining operation, such as a cutting operation with a specific tool. Each line in a block is labeled with the letter N and a number.

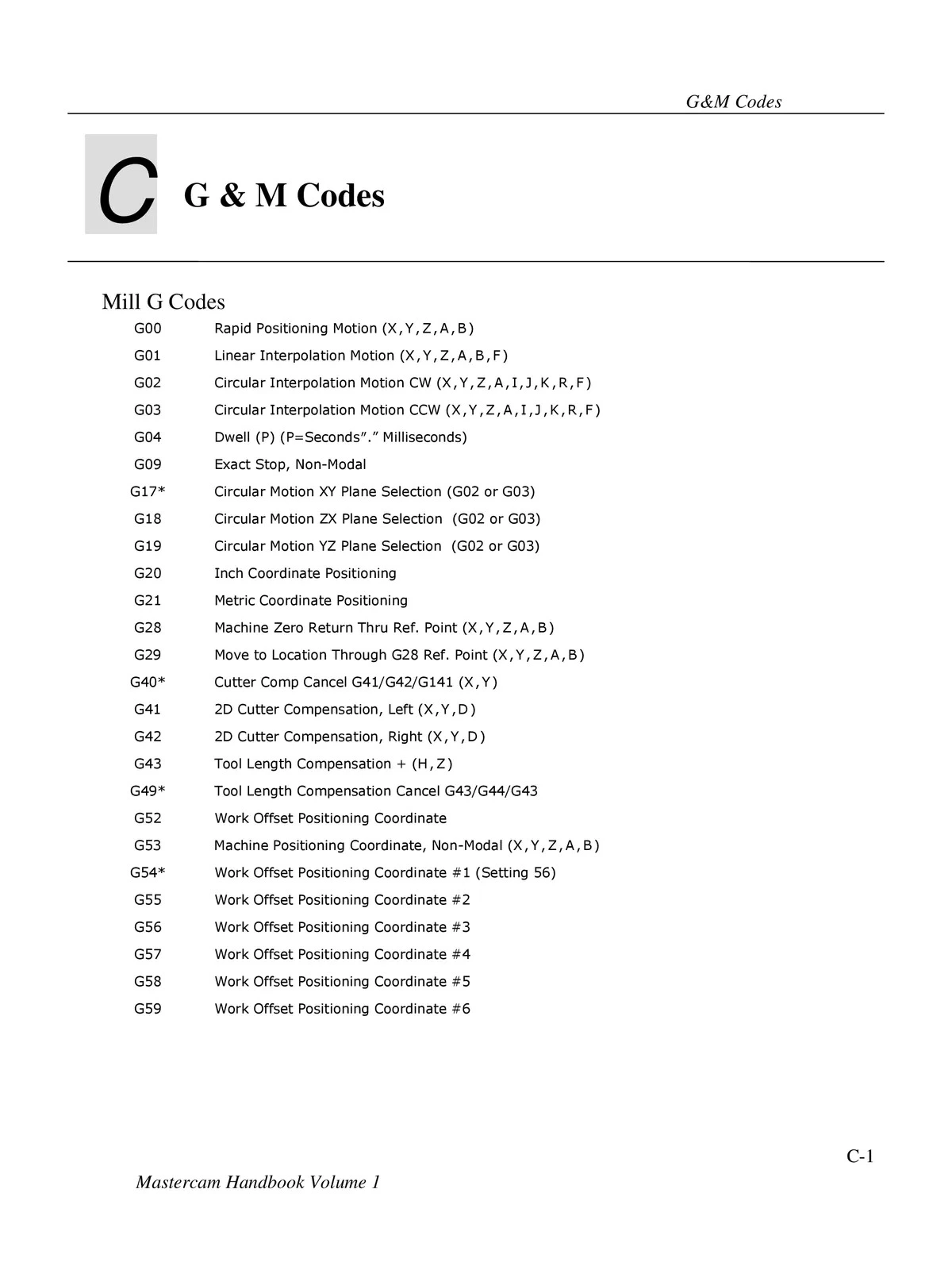

G Code List

| G code | Description |

|---|---|

| G00 | Rapid traverse |

| G01 | Linear interpolation |

| G02 | Circular interpolation CW |

| G03 | Circular interpolation CCW |

| G04 | Dwell |

| G09 | Exact stop |

| G10 | Programmable data input |

| G20 | Input in inch |

| G21 | Input in mm |

| G22 | Stored stroke check function on |

| G23 | Stored stroke check function off |

| G27 | Reference position return check |

| G28 | Return to reference position |

| G32 | Thread cutting |

| G40 | Tool nose radius compensation cancel |

| G41 | Tool nose radius compensation left |

| G42 | Tool nose radius compensation right |

| G70 | Finish machining cycle |

| G71 | Turning cycle |

| G72 | Facing cycle |

| G73 | Pattern repeating cycle |

| G74 | Peck drilling cycle |

| G75 | Grooving cycle |

| G76 | Threading cycle |

| G92 | Coordinate system setting or max. spindle speed setting |

| G94 | Feed Per Minute |

| G95 | Feed Per Revolution |

| G96 | Constant surface speed control |

| G97 | Constant surface speed control cancel |

You can download the G Code List PDF using the link given below.